Zhejiang Babysun New Energy Technology Co., Ltd.

Founded in 2007, with more than 10 years’ industrial experience,

over 60 technician staffs and a professional engineering team,

we’re a China-based company focus exclusively on the sales,

production and development of solar water heater and related solar

energy products.

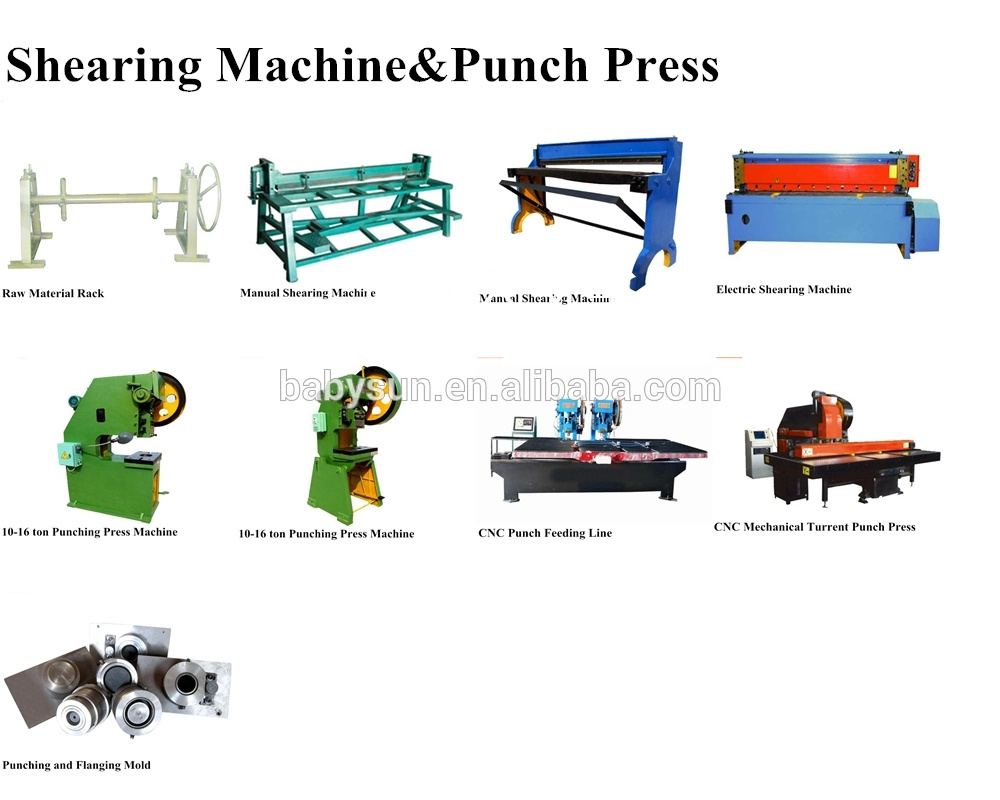

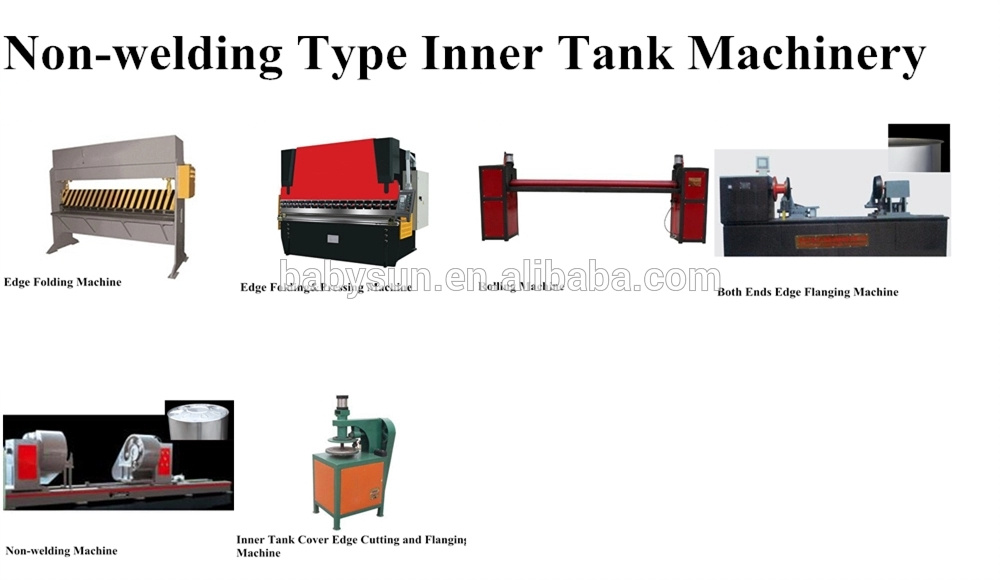

Our main products are solar water heater, solar collector,

solar water heater machinery, solar water heater accessories and

other solar related products.

We have CE, ISO, INMETRO certificates.